Protective finishing encompasses additional processes applied after printing to enhance durability and visual appeal. These value-added treatments help protect printed materials while improving their texture and overall presentation.

1. Lamination #

Lamination involves applying a thin plastic layer to paper or cardstock to protect the printed surface and enhance its look and feel.

- Matte Lamination: Provides a smooth, elegant finish with a soft tactile effect, making it ideal for premium designs. While it offers protection, it is more susceptible to scratches and fingerprints, especially on folded materials.

- Gloss Lamination: Delivers a vibrant, high-gloss sheen that enhances colors, making it a popular choice for brochures, menus, magazine covers, and presentation folders. It offers stronger protection than matte lamination.

- Soft Touch Lamination: Resembles a matte finish but adds a velvety texture that enhances the sensory experience. This luxurious coating provides extra depth and a refined touch.

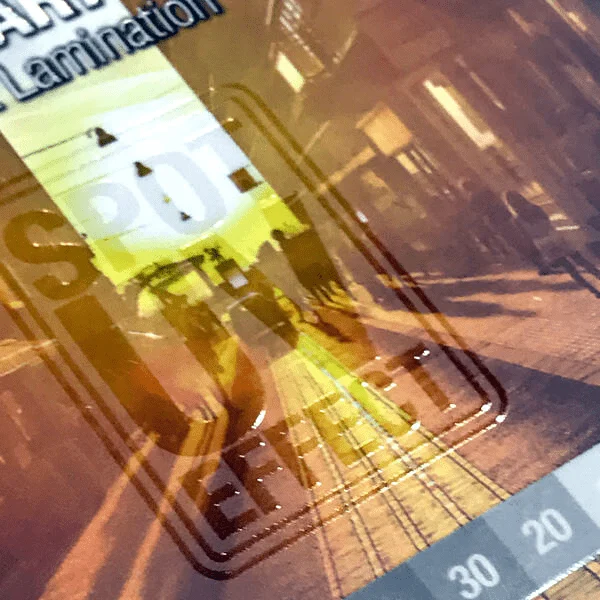

2. Spot UV #

Spot UV is a selective UV coating applied to specific areas of a printed design to create contrast in sheen and texture. It adds a glossy, raised effect to targeted elements, enhancing depth and visual impact.

3. Water-Based Varnish #

Also known as aqueous varnish, this eco-friendly coating is applied to printed materials to enhance vibrancy and provide protection. It reduces the risk of scratches, fingerprints, and scuffs while giving the design a polished look.

4. UV Varnish #

UV varnish is a clear, high-gloss coating applied wet and instantly cured using ultraviolet light. This finishing technique enhances shine, creating a reflective, eye-catching effect.